Howden's Ltd: Compressor Silencer

Howden Process Compressors are a manufacturer of gas compressor packages for blue chip oil companies. They specialise in rotary screw and turbo compressors, two systems which when in operation create large amounts of noise pollution. In order to reduce this noise pollution, compressor packages are comprised of two compressor silencers (inlet and outlet). It is within these compressor silencers that Howden identified an opportunity for a design project.

The aim of this project was to review Howden's existing designs to identify potential performance enhancements with regards to noise reduction. Furthermore, a database allowing easier specification of silencers to be used in conjunctions with specific compressor models should also be created to make it easier for clients to select the correct silencer package (compressor models are only compatible with certain silencer types due to size requirements, etc.)

The team were invited by Howden to see the on-site workshop and view the scale of the components being produced and assembled. The team then began with research into current silencers and a wide range of relatable technologies.

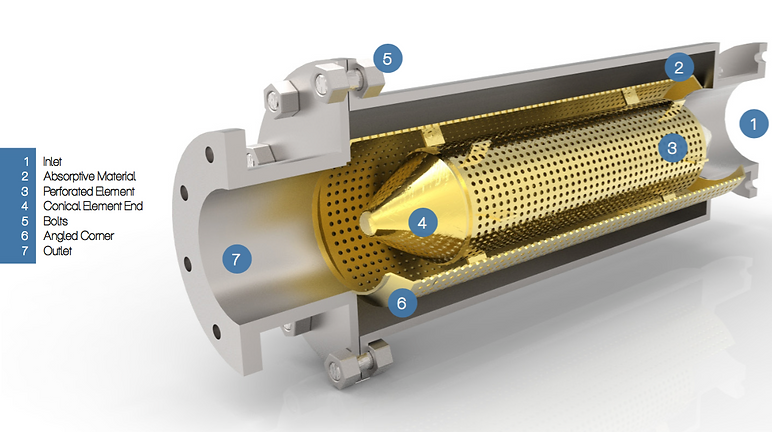

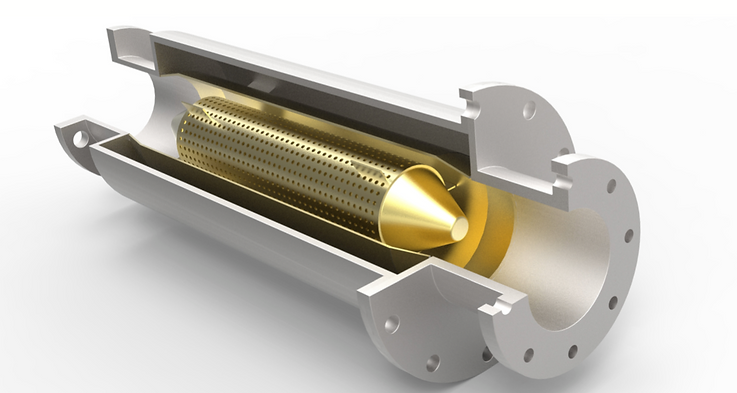

To assist with research and analysis, Howden delivered one of their current silencers to the laboratory, fully assembled. The team firstly documented the silencer and its casing before disassembling it and analysing the inner elements. Once the team had got the silencer open it was possible to analyse the central element and the absorptive material in more detail.

Concept Generation & Evaluation

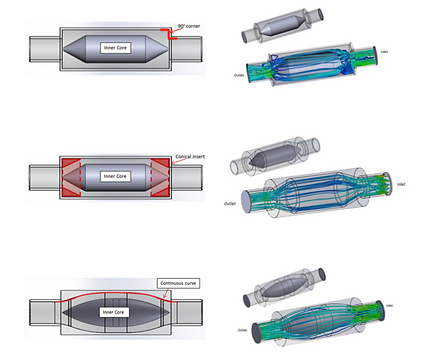

Early brainstorming was ‘loose’ and took all ideas into consideraton without rejecting any. As the group’s understanding of current silencers and their acoustic principles grew, more relevant concepts were created. Despite being generated in a highly unstructured manner these ideas were based upon thorough research and literature reviewed for the project. Concepts were generated exploring the current silencer design against streamlined ideas. These concepts were generated on CAD software and Computational Fluid Dynamics was used to analyse gas flow. A controlled convergence matrix was then used to evaluate these concepts allowing for the strongest concept to be identified.

Technical Evaluation

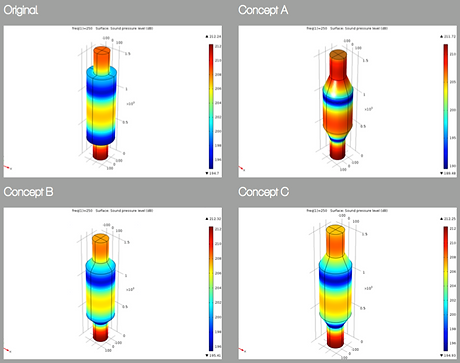

With the basic concept selected, the team used a CAD software system with an integrated acoustics module which would allow them to experiment with different angles and find the silencer design with the greatest noise reduction. Whilst it seemed to show that the adjusting of the angle changed the effectivenes, the software couldn’t prove this explicitly. At a number of the frequencies a large drop in the noise level is evident and the team believed that this goes some way to demonstrate that with the correct pre-production research and analysis Howden can produce more effective silencers for their systems.

The selected concept was developed in parity with all criteria of the PDS. As well as meeting the requirements of the PDS, the design was also subjected to processes allowing optimisation of manufacture and assembly procedures, specification of materials, and reduction of antcipated product cost. The product was tested using acoustic solving software; this allowed the designers to verify the validity of the design with respect to the sound reduction needs of the product.

Upon finalisation of a problem solution a database was adapted from current information provided by Howden. An intuitive interface was designed to streamline the silencer selection process.